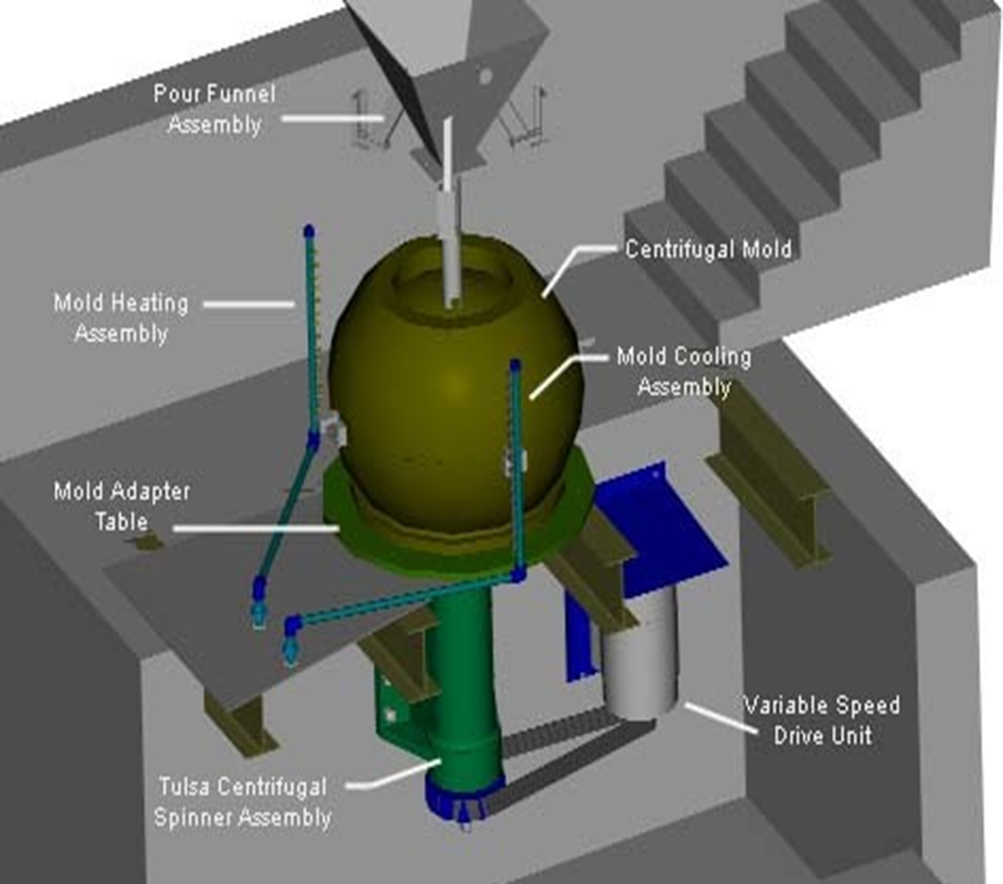

V10K Vertical Centrifugal Casting Machine

Vertical Centrifugal Casting Machines for the production of ferrous or non ferrous castings from a few pounds to several tons.

Tulsa Centrifugal Casting Machines provides the latest in machine design technology using 3D Modeling CAD programs. A variety of sizes are available from theVP Series of portable centrifugal casting machines to those that are mounted belowfloor level.

Vertical axis machines provide the greatest degree of casting configurations and capable of producing True Centrifugal, Semi-Centrifugal, and Centrifuge or pressure castings.

Standard Features

-

Electronically controlled vari- able speed drive unit

-

Drive controller

-

Operators Control console

-

Mold Water Cooling Manifold w/ Solenoid Valve

-

Mold Re-Heater Manifold w/ Air/Gas mixing tee assembly

-

Pouring Funnel

-

Mold Adapter Table

-

Spray wash gun

-

Sample of Centrifugal Mold Wash

-

Operators Manual