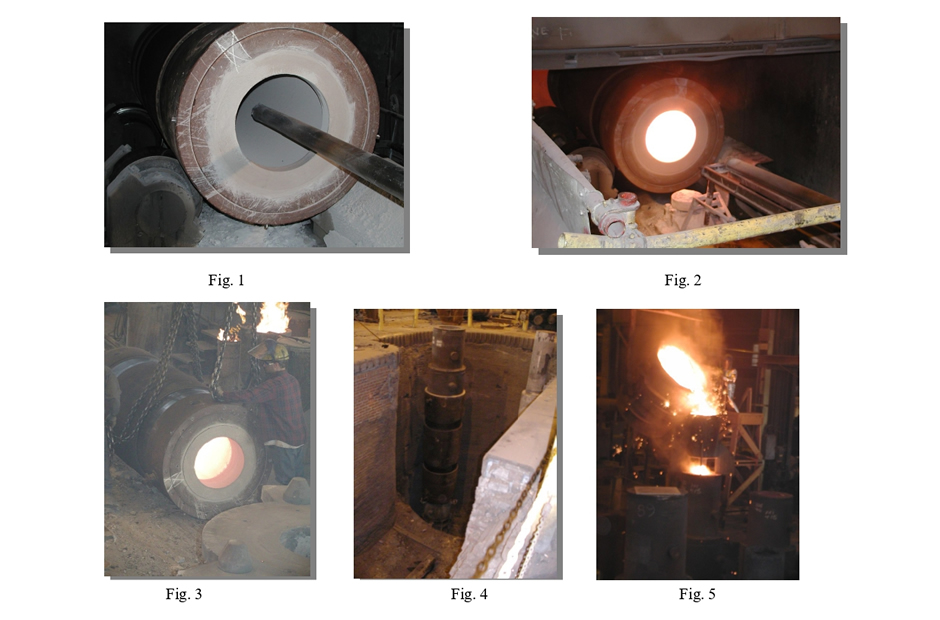

100K Horizontal Centrifugal Casting Machines - Roll

The Model 100K Series Hori- zontal Centrifugal casting ma- chines are designed to produce a variety of castings for the steel mill roll industry.

Castings produced in a hori- zontal axis approach 100% material yield and requires no gates or risers producing a “True Centrifugal” casting.

These trunnion type machines utilize permanent steel molds, sand lined flasks, & Chills.

Types of castings that can be produced

- Steel Mill Rolls

- Forming Rolls

- Extrusion Billets

- Ship shaft liners

- Bi-Metal Rolls

- Alloy Tubes

- Reformer Tubes

- Bushing Stock

Standard Equipment specifications

-

Spinner Base Assembly

-

Chill Thrust Assembly

-

ASL-20HD Spray Assembly

-

Operators Control Console

-

Pouring Car Assembly

-

Drive Unit Assembly

-

Variable Speed Drive Controls

-

Touch Screen Controls